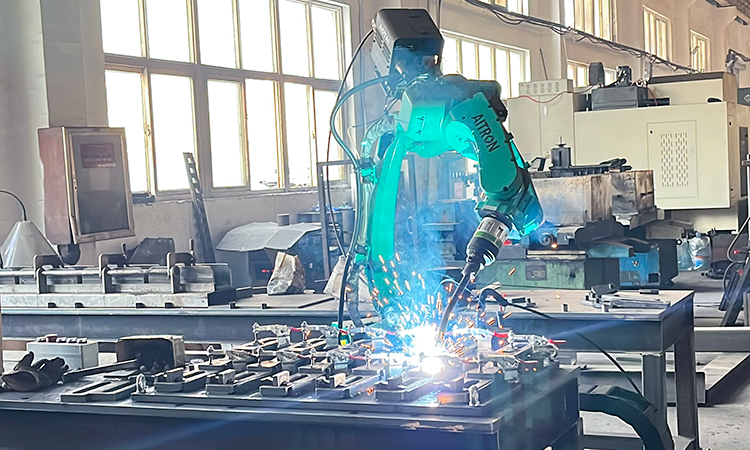

In the field of automotive repair equipment manufacturing, the introduction of robotic welding production lines represents a crucial intelligent upgrade. Its significance is first reflected in the revolutionary improvement of product quality: robots can perform welding operations with millimeter-level precision, completely eliminating the variability inherent in manual work and ensuring that the structural strength and weld consistency of core equipment meet the highest standards. Second, it significantly optimizes production efficiency and cost structures: robots can operate continuously and steadily, greatly increasing production tempo and output while reducing material waste and rework rates, thereby lowering comprehensive manufacturing costs in the long term. Furthermore, this represents a leap in the factory's technological image and market competitiveness—automated welding not only reduces the burden on workers in high-intensity tasks but also signals the enterprise's capability for large-scale, standardized production of high-end equipment, serving as a key technical endorsement to build trust with domestic and international clients. Robotic welding is not merely a process improvement but the foundation for the advancement of automotive repair equipment manufacturing toward a more precise and digitalized future.