Is the significant investment you made in your auto frame machine quietly depreciating due to a lack of maintenance? Many repair shops focus solely on its use while overlooking upkeep, ultimately leading to a decline in accuracy, reduced lifespan, and even safety incidents.

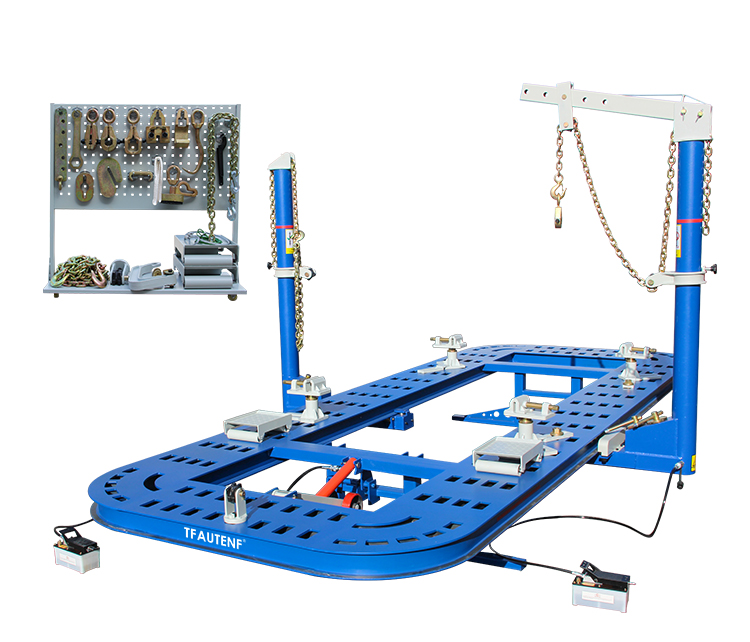

A lack of routine maintenance brings three major hidden costs: 1. Loss of Accuracy: Leaks in the pull tower hydraulic system or component wear can lead to inaccurate repair data, producing "substandard" vehicles. 2. Reduced Efficiency: Sticking fixtures and an underpowered hydraulic pump significantly extend repair times, dragging down bay turnover. 3. Safety Hazards: Damaged chains or compromised hydraulic lines can suddenly fail under high-pressure pulling, acting like a "ticking time bomb."

Therefore, making maintenance a standardized procedure is crucial. Daily checks of hydraulic fluid levels and line integrity; weekly cleaning of anchors and slide rails, along with inspection for chain wear; and periodic comprehensive performance verification by specialized technicians are essential. The minimal cost of preventive maintenance is far lower than the massive revenue loss from unexpected equipment downtime.