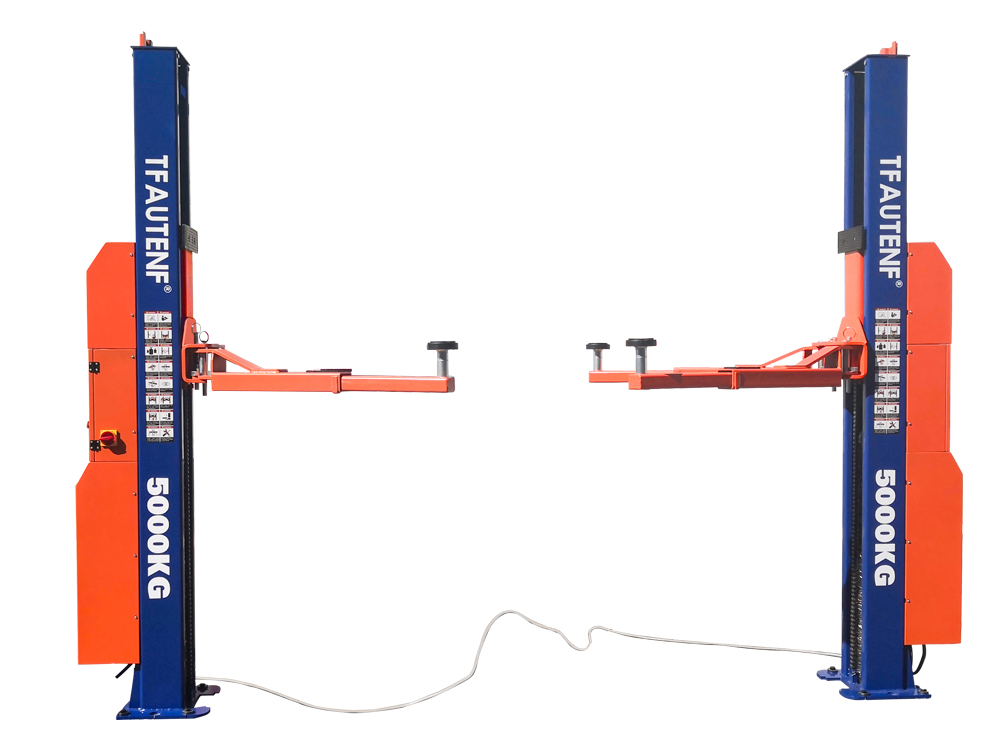

After five years in business, I've learned three expensive lessons the hard way. The two-post car lift I initially bought to save money has turned into my most costly "tuition fee."

Mistake 1: Choosing Cheap Equipment

At the time, I focused only on the price tag and opted for cheaper equipment. The result: within just six months, the lift started showing synchronization issues during operation, with the vehicle visibly tilting - frightening my workers from using it. When we opened it up for inspection, we found severely stretched and deformed synchronization cables of extremely poor quality.

Mistake 2: Neglecting After-Sales Support

The seller made grand promises of "lifetime maintenance" during the sale, but when problems arose, they stopped answering calls and messages. I ended up spending a significant amount to hire a professional technician to replace the entire set of cables and pulleys. The repair costs ultimately exceeded what I had saved on the equipment, plus the workshop was forced to shut down for two weeks.

Mistake 3: Using Without Maintaining

After the new equipment arrived, I only provided basic operational training to my staff but never established a maintenance schedule. We only oiled the cables when they showed rust, and cleaned the tracks when they jammed. It wasn't until the lift started making sharp, abnormal noises during operation that I realized the long-term lack of proper maintenance had caused irreversible damage to the equipment.

Now, that "bargain" lift can only handle light work. If I could turn back time, I would definitely choose high-quality products, clarify after-sales agreements, and establish proper maintenance records. I hope my experience makes this clear: every rational investment you make in a car lift is essentially buying insurance for your safety and business efficiency.