In repair shops and logistics centers, the drive system of heavy-duty truck lifts directly impacts equipment performance and operational costs. Currently, the mainstream solutions are hydraulic drive and mechanical drive systems, each with distinct advantages and limitations that require thorough understanding before selection.

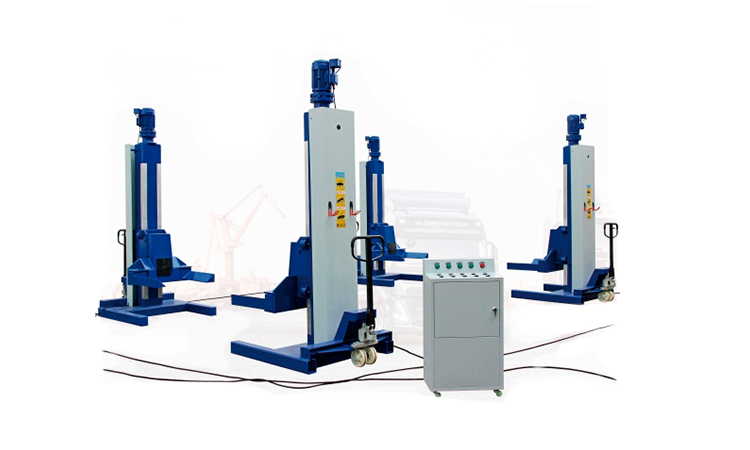

1. Hydraulic Drive System

Advantages: Smooth lifting operation, high load capacity (ideal for trucks over 10 tons), excellent shock absorption, and automatic balance adjustment.

Disadvantages: Complex structure, higher maintenance costs (regular hydraulic fluid replacement required), potential oil leakage risks, and reduced efficiency in low-temperature environments.

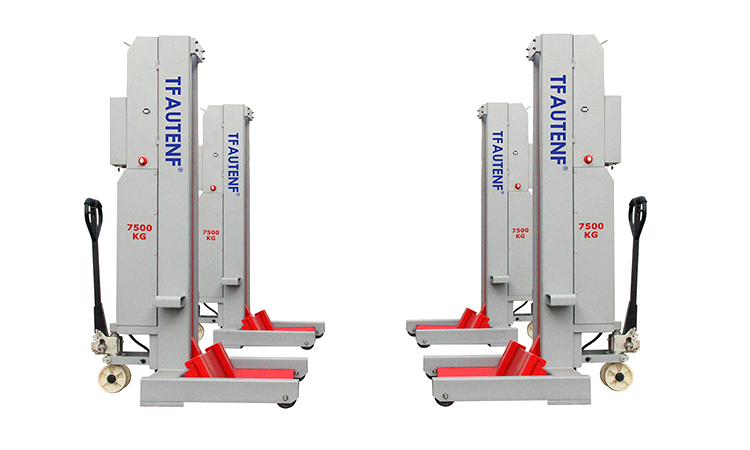

2. Mechanical Drive System

Advantages: Simple structure, lower failure rates, easier maintenance (only requiring chain/gear lubrication), higher energy efficiency, and longer lifespan.

Disadvantages: Slower lifting speed, noticeable vibrations, and lower overload tolerance (may cause structural deformation).

How to Choose?

Heavy-duty repair facilities: Prioritize hydraulic systems for large-tonnage requirements.

High-frequency operations: Mechanical drives are more economical for small-to-medium fleets with budget constraints.

Looking ahead, the line between these systems may blur with the adoption of electro-hydraulic hybrid technology. However, for now, rational selection based on actual working conditions remains essential.