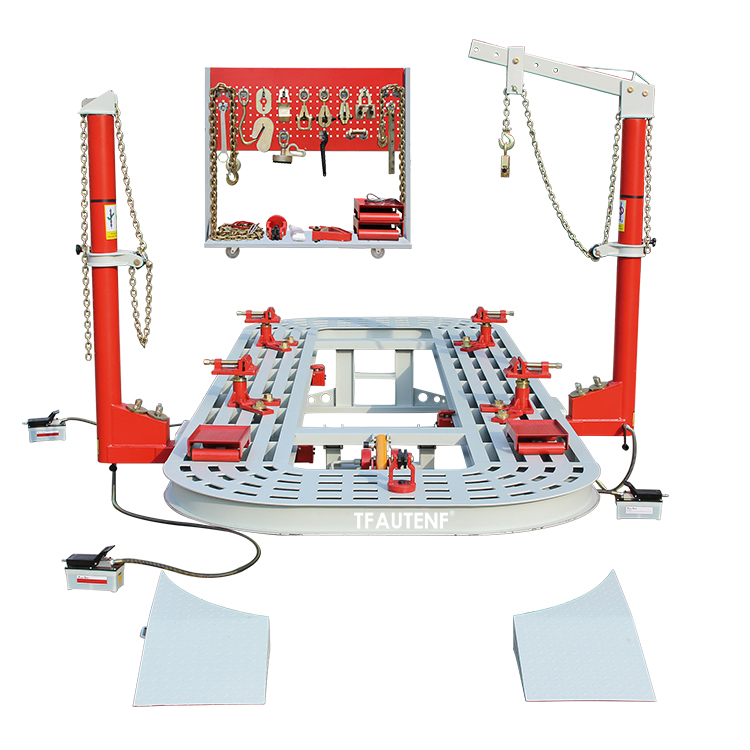

In the field of automotive repair, the auto frame machine is a core piece of equipment for repairing deformed vehicle frames. Different frame materials require corresponding correction techniques, leading to significant differences when working with manganese steel frames versus I-beam frames.

The manganese steel auto frame machine utilizes a multi-point hydraulic stretching system combined with high-precision measurement technology, enabling precise repairs that accommodate the high strength and toughness of manganese steel. Its advantage lies in localized micro-adjustments, making it particularly suitable for repairing frame deformations in off-road vehicles and construction equipment that endure complex stress loads. However, operators must carefully control stretching force to avoid damaging the material's internal structure.

The I-beam auto frame machine, on the other hand, focuses on overall stretching, using mechanical clamps to secure and straighten the standardized I-beam structure. This equipment is simpler in design and more cost-effective, making it ideal for repairing overall deformations in economy vehicles. However, due to the I-beam's weaker torsional resistance, extra care must be taken to prevent secondary deformation during correction.

In summary, the manganese steel auto frame machine is better suited for precision repairs on high-performance vehicles, while the I-beam auto frame machine is more efficient for economical, rapid repairs. Repair shops should select the appropriate correction method based on vehicle type and damage severity.