Working principle

- Heavy-duty hydraulic truck lift: rely on liquid pressure transmission to achieve lifting action. The hydraulic pump transmits hydraulic oil to the hydraulic cylinder, and pushes the piston movement through the liquid pressure, thus driving the lifting platform.

- Heavy machinery lifting machine: usually use screw nut mechanism, chain, gear and other mechanical structures to achieve lifting. Taking the screw nut mechanism as an example, the motor generates power and drives the screw to rotate after decelerating through the reducer, and the nut moves up and down along the screw to achieve the lifting function.

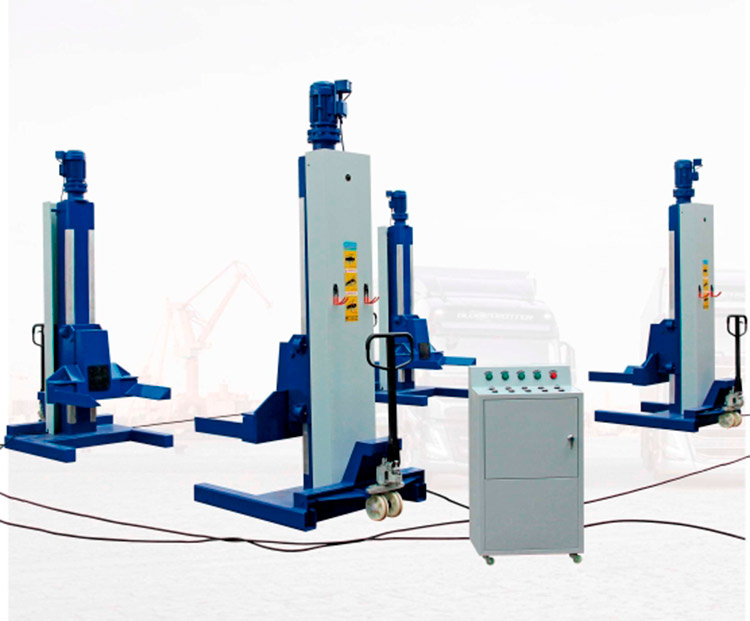

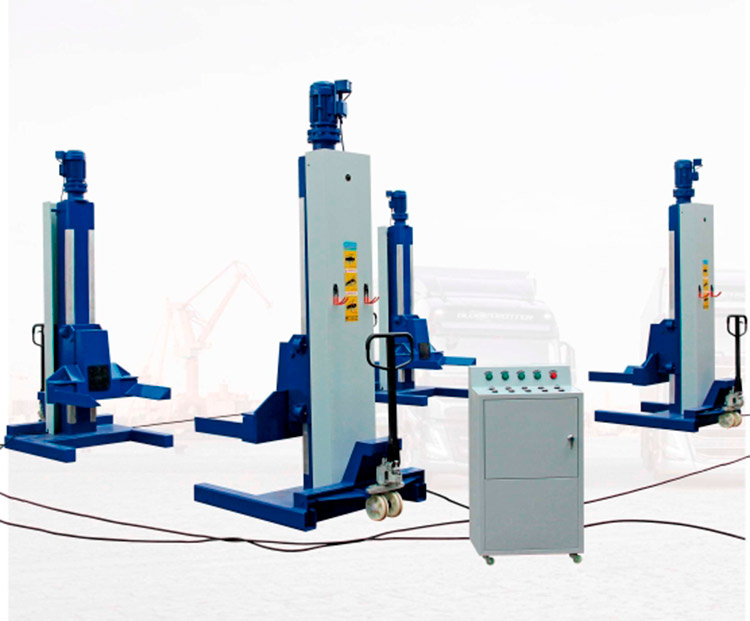

Structural characteristics

- Heavy-duty hydraulic truck lifts: the structure is relatively compact, because the components of the hydraulic system can be arranged more flexibly. For example, the hydraulic cylinder can be hidden in positions such as the inside of the column, making the overall appearance more concise.

- Heavy machinery lifts: generally have obvious mechanical transmission parts, such as motors, chains, screws, etc., exposed. So the structure is often more complex, the volume may be relatively large, occupy more space.

performance

Heavy-duty hydraulic truck lift: smooth work, can achieve accurate speed control and positioning, and lifting force is large, in the lifting process can maintain good stability, suitable for high accuracy and stability requirements of the occasion.

- Heavy machinery lifts: may produce large noise and vibration during operation. This is caused by friction and collision between mechanical transmission components. And with the increase of use time, mechanical wear will gradually increase, thereby reducing transmission efficiency and working life.

Scope of application

Scope of application

Heavy-duty hydraulic vehicle lift: often used in automotive maintenance, large-scale equipment installation and commissioning of lifting smoothness and accuracy requirements of the scene. Widely used in automobile 4S shops, large repair shops and other places, it can lift cars safely and smoothly, and facilitate maintenance personnel to operate.

Heavy machinery lifts: In some cases where the accuracy requirements are not particularly high, but there are certain requirements for structural simplicity and cost, it is used more, such as some simple cargo handling, material lifting in small factories.

Performance and benefits

- Better performance: Hydraulic lifts provide a smoother lifting process, higher lifting power and more precise control. For some application scenarios with high lifting requirements, these performance advantages of hydraulic lifts are irreplaceable, so their prices will be correspondingly higher.

- Long-term benefits: From the perspective of long-term use, although the early purchase cost of the hydraulic lift is high, due to its good stability, long life, relatively simple maintenance and other advantages, it can maintain a good working condition for a long time, reduce the production interruption and additional costs caused by equipment failure and maintenance, and the comprehensive cost efficiency is higher, which is also reflected in its higher price.

Scope of application

Scope of application